- #Make feature cam post read in diam how to#

- #Make feature cam post read in diam manual#

- #Make feature cam post read in diam full#

- #Make feature cam post read in diam code#

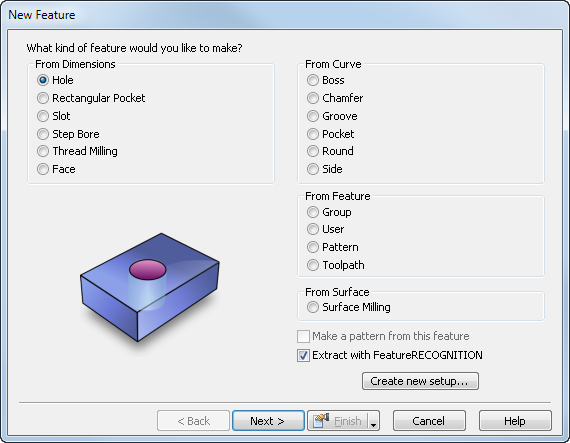

It’s meant to automate and simplify repetitive and common tasks, such as drilling holes. Put simply, a canned cycle is a command that gives the machine instructions for a pattern of movements. That said, canned cycles are generally pretty consistent among any Fanuc-based machines. Keep in mind that every machine controller will have its own quirks and custom codes, so it’s always a good idea to check the manual.

#Make feature cam post read in diam how to#

It’s not exhaustive, covering every little thing that can be done with each code, but it’ll cover the basics of what they do and how to pull them off successfully. The intent of this article is to be an introduction to canned cycles in CNC 3-axis mill programming, based on the Fanuc controller. Even if you’re not coding by hand every day, this will allow you to read the program to know what’s going to happen before the line is executed (handy for proveouts), and it’ll equip you with what you need to debug issues as they come up. While some shops do run exclusively with CAM software, it’s a huge asset to understand the codes used to program machines.

#Make feature cam post read in diam manual#

Some say that since most people use CAM software, there is no longer any need to learn manual programming.

For instance, if the Z coordinate at sub-spindle left is -63 inches, the sub-spindle solid should have a local coordinate system where the Z point 'to the right' so that it interprets 'move minus Z' as 'move left'.When you’re starting in CNC, the amount of codes and cycles you need to learn can seem a little overwhelming at first. In particular, the sign of the movement should match the local coordinate system of the sub-spindle solid in the machine design file. These are the options Machine Z coordinate at sub-spindle home and Machine Z coordinate at sub-spindle max (left).

For example, a main-spindle-side lower turret is much different to a sub-spindle-side lower turret.

#Make feature cam post read in diam code#

#Make feature cam post read in diam full#

md in the XBUILD menu) - We recommend that you set this to machine.md (without a full path), so that the simulation looks for the MD file in the same directory as the CNC file. Only the first two apply to milling machines all apply to lathes and turn/mill machines. There are a few interactions that you need to be aware of. For example, if you have a lathe without an optional sub-spindle, the main spindle simulation of the machine works fine with a post that doesn't support a sub-spindle. In general, a Machine Design file is not necessarily tied to a particular post.

0 kommentar(er)

0 kommentar(er)